Excillium AB has gained access to EuroHPC JU supercomputer MeluXina in Luxembourg. They have applied for computing time using the Benchmark Access Call. During their allocation, they will perform liquid metal jet simulations using OpenFoam. ENCCS expert Qiang Li provided support both during the application process and the access period.

Organisations involved

Excillum AB is a global leader in the field of advanced microfocus and nanofocus X-ray sources. It produces cutting-edge high-end X-ray sources utilizing the patented metal jet anode technology. The fluid dynamics including velocity, pressure, turbulence distribution, and liquid-vacuum interface are frequently challenged engineering parameters in their future development. CFD simulation is a fast and cost-effective approach for evaluating a large number of designs.

Technical/scientific challenge

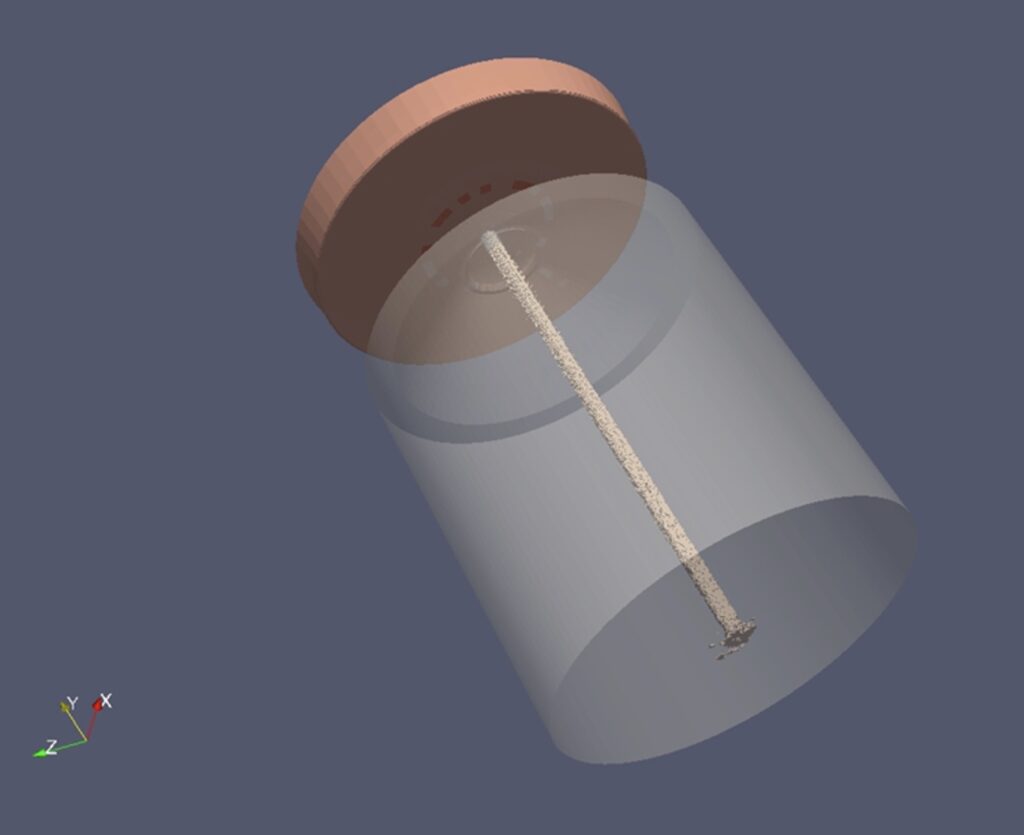

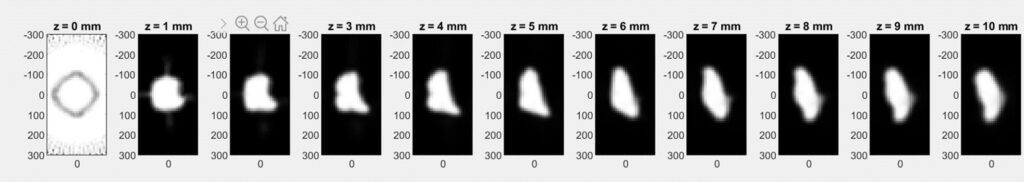

Excillum develops CFD codes using OpenFoam to simulate liquid metal jets of different configurations. The grid size, together with the time-stepping size decides the resolution of a simulation. During the simulations, micro-scale spatial resolution and micro-second temporal resolution provide accurate fluid dynamics information regarding jet behaviours such as deformation, shifting, twisting in a high vacuum environment. In one of the studies, they will investigate how deviations from the ideal nozzle shape will influence the jet shape. Significant amount of computing resources is required for a simulation answering this question.

Proposed solution

The CFD application is developed using existing libraries provided by OpenFOAM v1812. The Excillium team will first launch a series of benchmark tests to assess the performance of OpenFOAM for our user case. Depending on the results, they may further carry out some related optimization work. The goal is to find the optimal setup for performance given a certain resolution of the simulation.

Business impact

Accessing a supercomputer will allow Excillium to conduct several numerical experiments for parameter studies which saves both time and costs compared to conducting the same number of physical experiments in a lab. By this, they will shorten the lead time between the concept & feasibility phase and the development phase in our product life cycle, which is a key to achieving efficient development.

Benefits

- Parameter studies to avoid lab tests aiming at design optimization, which saves working hours and cost on test materials

- Numerical experiments to revel new knowledge related to improving the configuration of key components in our product

- Ability to run simulation of different kind, e.g., CFD, optical simulation, particle simulation, in a single platform, which increase efficiency

Access European supercomputers for your projects

Any company based in Europe can gain access to a EuroHPC JU supercomputer. Learn more here.