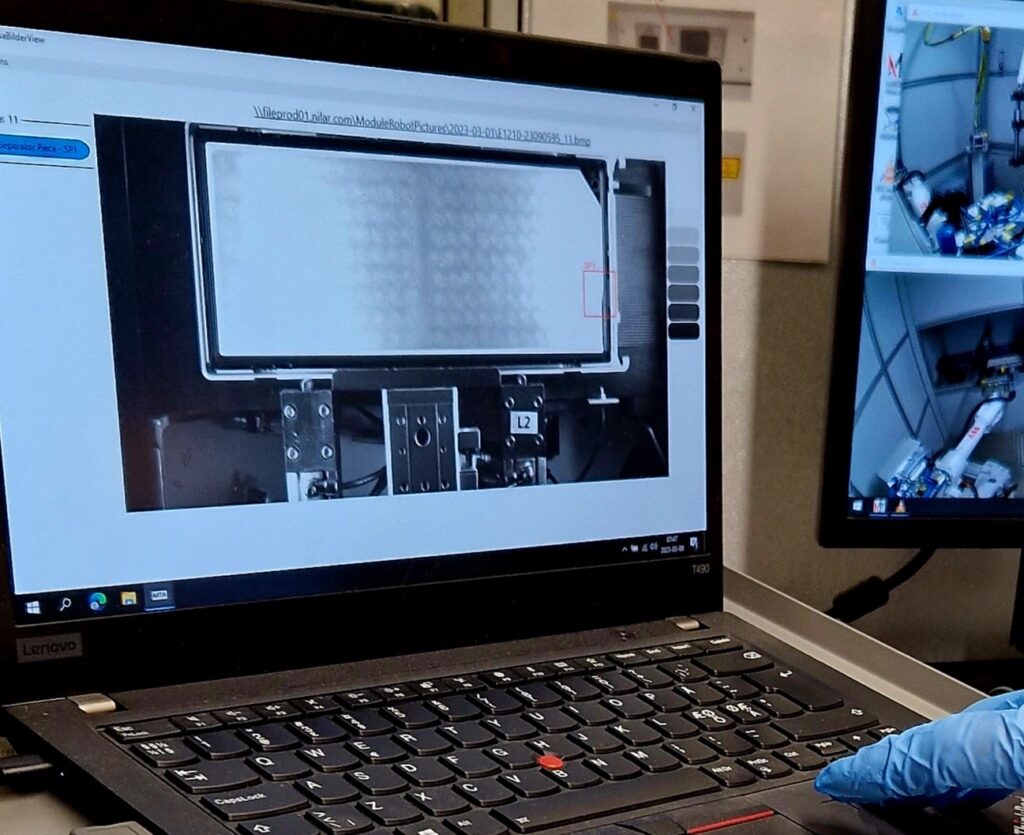

Swedish battery manufacturer Nilar AB accessed EuroHPC JU supercomputer Vega and finished their project in training AI models to automate battery inspection during the manufacturing process.

Quality inspection is an essential part of the battery manufacturing process, since quality determines battery performance, lifespan, and safety. Inspection should ideally be done for every part of every battery, but the high production rate makes this very difficult to achieve without automation.

RISE and Nilar AB have leveraged the computational resources that the EuroHPC JU Vega cluster provides and the large image datasets Nilar has collected from their assembly lines to develop an AI-based computer vision solution as a first step towards complete automation of Nilar’s quality inspection process.

From the supercomputing access, Nilar is already seeing benefits from the solution, such as being able to spot negative trends in quality earlier, which enables faster adjustment of process parameters to reverse these trends. This has helped reduce their scrap rate, which in turn has led to a positive impact on their business.

Did you know that your company/organisation can access a European supercomputer for free and speed up your workflow? Learn more here.